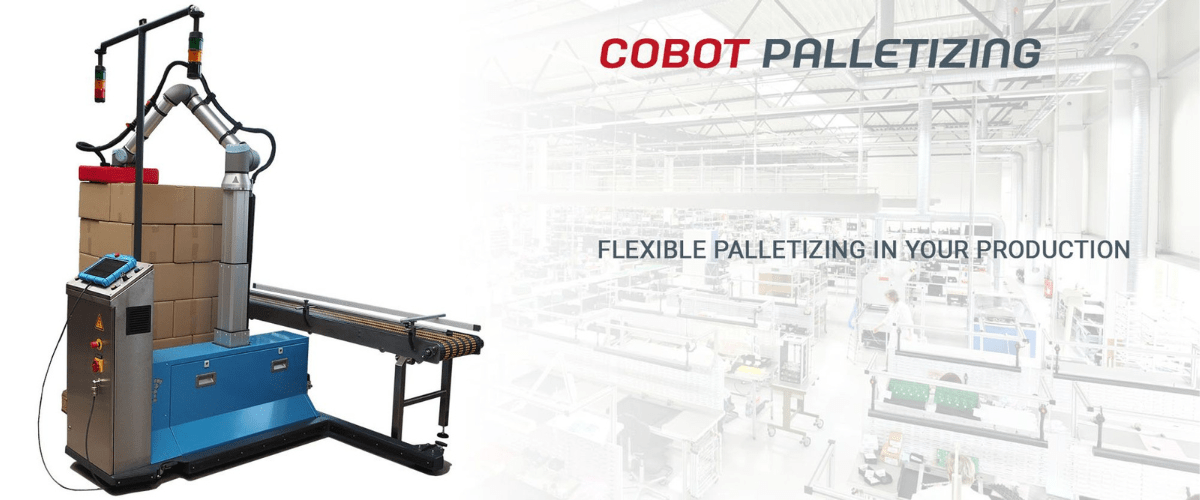

Palletising with Coboti offered by DAAC digital

The most flexible palletising solution

DAAC digital brings you an easy-to-operate, ready-to-use and fully integrated palletizing solution from DAHL Robotics. It allows you to automate unpleasant, cumbersome and time-consuming tasks without making significant adjustments to your production setup.

Available in two versions with maximum loads of 12.5 kg and 20 kg, the compact kit positioned on a mobile, rolling frame requires relatively little space and can be used flexibly in your facility, wherever needed.

The palletiser consists of a control cabinet unit with control panel and – depending on the version – a Cobot Universal Robots UR-10 eSeries or Doosan H2017, each serving two pallet positions.

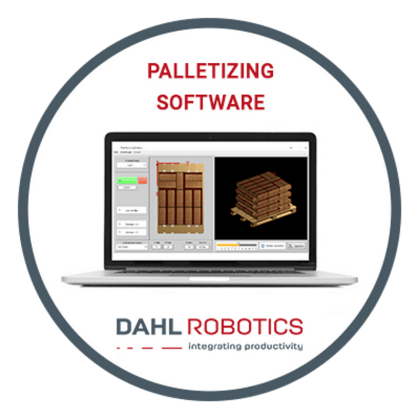

Palletizing Software

DAHL LogiSort allows you to create graphic packaging designs without programming. Set up identical or varied palletising layers in just minutes – offline, without disrupting the ongoing process.

Collaborative Robotics

In the Universal Robots version, a Cobot UR10e stacks up to a package height of 1,100 mm, optionally up to 2,000 mm with the Ewellix Liftkit (maximum speed 80 mm/s). In the Doosan H2017 version, the palletising height is 2,200 mm with an even higher load.

Vacuum grip

Housing for collaborative operation at head height: an ultra-light surface vacuum gripper with soft-touch surfaces and integrated vacuum creation system ensures safe and efficient handling in any situation.

The mobile cobot palletiser can be additionally equipped with a vision system for position and orientation detection. An intralogistics connection via conveyor belts or to a driverless transport system (AGV/AMR) can also be easily realised.

Certification as a Universal Robots+ application kit characterises the palletiser from DAHL Robotics as a particularly safe and simple automation. Works efficiently and stops immediately when you touch it!

- Suitable for a wide range of industries, the dual pallet position palletizer ensures a continuous workflow with a combination of time-tested automation modules.

- CE certified MRK application: a bulky protective housing can be dispensed with to save space. The collaborative palletising solution ensures high safety.

- The rolling frame and compact design ensure high flexibility and good process integration in your company.

- It’s simple to use, with easy-to-understand controls, providing hassle-free automation.

- The Cobot mobile palletizer helps you automate heavy and time-consuming tasks. So you can use your staff in more efficient ways!

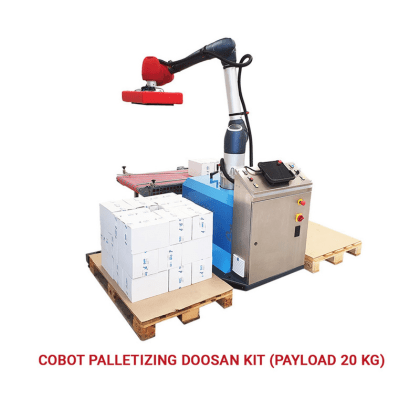

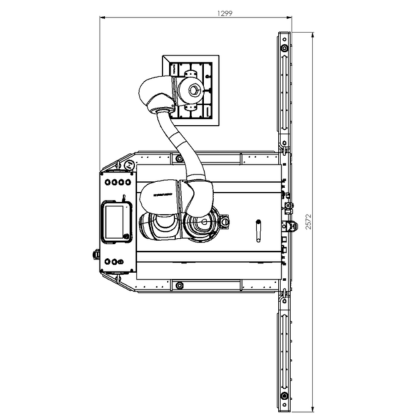

Doosan mobile palletizing kit

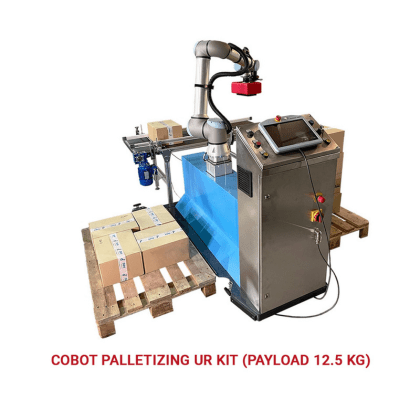

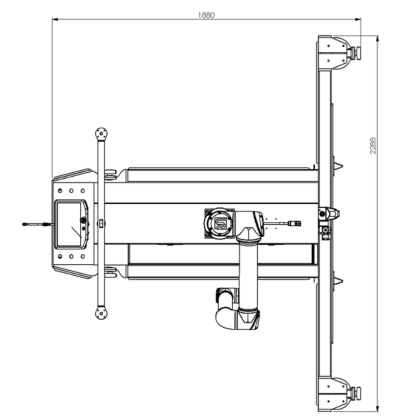

Universal Robots mobile palletizing kit

Technical data

DOOSAN H2017 KIT

Payload 20.0 kg

Maximum load capacity: 20 kg (approx. 17 kg net/package) Robot: Doosan H2017 Cobot Kit dimensions* (WxHxD): 2,572 x 1,299 mm Kit tare weight: approx. 500 kg Pallet types: tandard EUR, CP1, CP2 Robot range: 1,700 mm Maximum stacking height**: 2,200 mm Temperature range: -5 to 45 °C

Universal Robots KIT

Payload 12.5 kg

Maximum load capacity: 12.5 kg (approx. 10 kg net/package) Robot: Cobot Universal Robots UR10e Kit dimensions* (WxH): 2,288 x 1,880 mm Kit tare weight: approx. 400 kg Pallet types: max. Standard EUR Robot range: 1,300 mm Maximum stacking height**: 2,000 mm Temperature range: 0 to 50 °C

Doosan / Univeral Robots common parameters

Pallet positions: 2; Ready for AGV connection; Power supply: 16A, 400V; Compressed air: 6 bar; Interface kit: I/O (Profinet, Modbus, TCP IP = option), other interfaces on request; Safety: CAT. 3 Pld, CE compliant, according to TS 15066, additional bumpers; Cycle speed: Depending on product weight, packaging model and pallet type 4-36 packs/min;

*without conveyor belt, including pallets EUR.

** exact height depending on pallet model, packaging dimensions & pallet type.

Subject of delivery DAHL Cobot palletizer

1x mobile frame with rollers

1x control cabinet unit and control panel

1x suspension with car warning light (UR version only)

1x collaborative robot

1x Surface vacuum gripper with 2 folding (2 suction circuits)

1x Protective housing set for robot joints and gripper (touch)

1x Flexible cable/hose guide set for robot

1x DAHL LogiSort palletising software DAHL LogiSort

Intralogistics connection

For seamless integration into your autonomous intralogistics goods flow, the two palletising positions of the Cobot compact palletiser are optimally designed to be controlled by self-driving vehicles.

The video shows an example of logistics with Nipper Pallettruck and Robotize GoPal. Here you can find out more about our recommended AGVs and AMRs

Are you ready to automate your palletising process?

At DAAC digital, we bring the benefits of modern robotics to your business. In collaboration with DAHL Robotics, we offer a compact and flexible palletising solution designed to simplify and streamline workflow through the use of intelligent pallet trucks.

Designed for smooth integration, our systems are ready to take on tough tasks, optimising the palletising process without extra effort on your part. The variety of models, supporting weights of up to 12.5 kg or 20 kg, ensures that you will find the perfect solution for your current production needs without complex adjustments.

Choose DAAC digital for a smooth transition to maximum efficiency.